Fish Canning Processing Equipment Supplier - Chinese Manufacturer, Factory, Supplier

A fish canning processing equipment supplier provides comprehensive machinery and turnkey solutions for the seafood industry, enabling processors to produce high-quality canned fish efficiently and safely. From small-scale operations to fully automated industrial plants, these suppliers specialize in delivering systems that cover the entire production cycle, including cleaning, cutting, cooking, sterilization, filling, seaming, labeling, and packaging.

Modern fish canning processing equipment suppliers offer advanced automation technologies that reduce labor costs, improve throughput, and ensure uniform product quality. Automated conveyors, precision filling machines, and high-speed seaming systems allow processors to maintain consistent weight and portion control for each can, whether producing sardines, mackerel, tuna, or salmon. This level of precision is crucial for meeting both local and international market standards.

Flexibility is a major advantage of working with professional suppliers. Equipment can be customized to handle a wide range of can sizes—from small single-serve cans (70–125g) to standard retail packs (145–155g) and bulk cans (400g or larger). Many suppliers also provide options for integrating sauces, oils, brine, or other additives directly into the filling process, allowing processors to diversify product offerings without investing in separate production lines.

Hygiene and safety are prioritized across all stages of the production line. Leading fish canning processing equipment suppliers use food-grade stainless steel, easy-to-clean surfaces, and comply with HACCP, ISO, and CE standards. Advanced sterilization units ensure that canned fish remains safe for consumption and shelf-stable for extended periods, meeting stringent international food safety regulations.

Turnkey solutions often include installation, operator training, maintenance support, and spare parts supply, ensuring that seafood processors can achieve maximum uptime and efficiency. Suppliers also provide technical consultation to optimize workflow, reduce bottlenecks, and enhance overall ROI.

By partnering with a reputable fish canning processing equipment supplier, companies can not only improve operational efficiency but also scale production to meet increasing global demand. These suppliers enable processors to deliver safe, consistent, and high-quality canned fish products that satisfy consumer expectations in both domestic and international markets.

Choosing the right supplier is critical for long-term success, as it affects production reliability, product quality, and the ability to respond to market trends quickly. With modern equipment and professional support, seafood processors can achieve higher productivity, maintain compliance with food safety standards, and expand their presence in the competitive global seafood industry.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

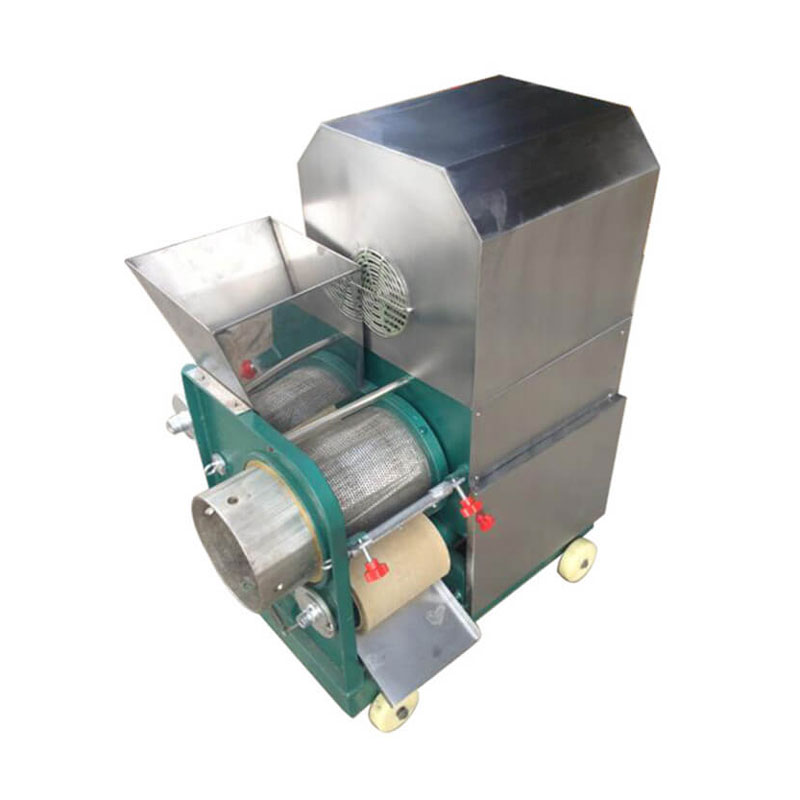

Pet Fish Meat Canning Production Line Fish Deboner Machine

Fish Deboner Machine Microwave Pigskin Puffing Machine

Microwave Pigskin Puffing Machine Cereal Bar Production Line

Cereal Bar Production Line Double-Wok Dual-Temperature Induction Cooker

Double-Wok Dual-Temperature Induction Cooker Semi-automatic Potato Crisps Production Line

Semi-automatic Potato Crisps Production Line French Fries Frying Machine

French Fries Frying Machine Vegetable Dicing Machine

Vegetable Dicing Machine Meat Smoking Machine

Meat Smoking Machine