Fish Processing Equipment Manufacturers - Chinese Manufacturer, Factory, Supplier

Leading fish processing equipment manufacturers in China, such as Qingdao Hongshengyuanlin Co., Ltd., specialize in supplying advanced machinery for the modern seafood industry. Their products cater to every stage of fish processing — from cleaning, filleting, and portioning to freezing, canning, and packaging — ensuring efficiency, hygiene, and consistent product quality.

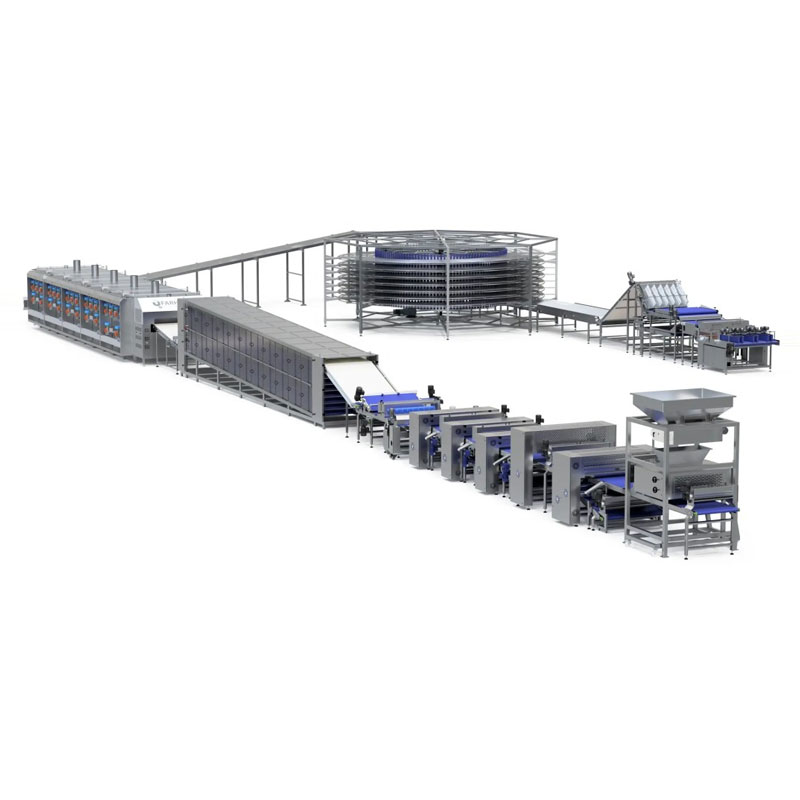

Modern fish processing lines require equipment that can handle delicate raw materials while maintaining freshness, texture, and nutritional value. Manufacturers provide complete production systems, including automatic washing and grading machines, filleting and skinning units, portion cutters, IQF freezers, and vacuum packaging machines. Each unit is built with food-grade stainless steel, corrosion-resistant surfaces, and easy-to-clean designs, ensuring compliance with international hygiene standards such as HACCP, ISO22000, and CE.

Automation plays a central role in contemporary fish processing. Integrated PLC control systems, touchscreen interfaces, and real-time monitoring allow precise operation, minimizing human error and labor costs. Specialized machines such as automatic can fillers, retort sterilizers, and glazing systems help manufacturers produce high-quality canned or frozen fish products efficiently.

Top fish processing machinery manufacturers provide custom turnkey solutions, including factory layout design, equipment customization, installation, commissioning, and operator training. Lines can be tailored for specific species, such as tuna, mackerel, sardines, and salmon, and adapted to small-scale or large industrial operations. Optional features like grading, weighing, and labeling enhance product standardization and traceability, which is crucial for both domestic distribution and export markets.

Chinese suppliers are increasingly recognized globally for their engineering innovation, cost-effective production, and after-sales support. Export projects span Southeast Asia, the Middle East, South America, and Europe, where the demand for hygienic, automated fish processing continues to grow.

By combining technological expertise, customized designs, and global project experience, these manufacturers help fish processors modernize their plants, improve efficiency, and ensure consistent product quality. Partnering with a professional fish processing equipment manufacturer guarantees reliable operation, higher productivity, and long-term profitability in the competitive seafood industry.

Types of Fish Processing Equipment & Applications

| Category | Main Equipment | Core Function | Applications |

|---|---|---|---|

| Cleaning & Grading | Automatic washers, water baths, grading conveyors | Remove scales, slime, and debris; sort fish by size | Tuna, mackerel, sardine, salmon |

| Filleting & Skinning | Filleting machines, skinning units, portion cutters | Precise fillet cutting, skin removal, portion control | Fresh fillets, frozen fish portions |

| Deboning & Trimming | Mechanical deboners, trimming machines | Extract lean meat and remove bones | Fish nuggets, minced fish, surimi production |

| Canning Equipment | Automatic can washers, fillers, seamers, retort sterilizers | Filling, sealing, and sterilizing canned fish | Sardine, tuna, mackerel, anchovy cans |

| IQF & Freezing Systems | IQF freezers, glazing machines, spiral freezers | Rapid freezing and surface protection | Frozen fillets, whole fish, seafood mixes |

| Packaging & Labeling | Vacuum packing machines, tray sealers, labeling systems | Preserve product, ensure traceability | Retail packaging, export-ready products |

| Drying & Smoking | Drying ovens, smoking chambers, flavor injectors | Dehydration, smoking, and flavor enhancement | Dried fish, smoked salmon, seafood snacks |

| Quality Inspection & Grading | Vision sorters, metal detectors, weight graders | Ensure product quality, size uniformity, and safety | Export lines, HACCP-compliant plants |

| Conveying & Auxiliary Equipment | Conveyors, water pumps, chillers, ice machines | Material transfer, temperature control, storage | Integrated fish processing lines |

| Support Systems | PLC control panels, monitoring software, energy-efficient motors | Automation, process monitoring, energy optimization | Complete production line integration |

Qingdao Hongshengyuanlin Co., Ltd. provides comprehensive turnkey solutions for fish processing plants, delivering fully integrated production lines tailored to client needs. From initial plant design to equipment manufacturing, installation, commissioning, and operator training, every step is managed by our experienced engineering team to ensure smooth and efficient operations.

Our turnkey solutions cover the full spectrum of fish processing, including cleaning, grading, filleting, deboning, freezing, canning, and packaging. Each production line is designed with modular layouts, allowing scalability and flexibility to accommodate different species, production capacities, and regional market requirements. Advanced PLC control systems, touchscreen interfaces, and real-time monitoring ensure precision, product consistency, and energy efficiency throughout the process.

We have successfully executed projects across Southeast Asia, the Middle East, South America, and Europe, gaining international recognition for reliability, innovation, and cost-effective solutions. Optional modules such as automated grading, weighing, labeling, and metal detection systems further enhance product standardization and traceability, meeting both domestic and export standards.

By integrating state-of-the-art equipment with customized engineering services, Qingdao Hongshengyuanlin enables clients to modernize their fish processing facilities, reduce labor costs, improve output quality, and achieve long-term profitability. Our dedicated technical support and after-sales service guarantee continuous operation and minimal downtime, making us a trusted partner for global seafood producers.

Contact us today to learn how our turnkey fish processing solutions can transform your production line into a fully automated, high-efficiency facility.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Chicken Egg Peeling Machine

Chicken Egg Peeling Machine Automatic Twisting Quantitative Sausage Stuffer Machine

Automatic Twisting Quantitative Sausage Stuffer Machine Automatic Sausage Clipper Machine

Automatic Sausage Clipper Machine Carrot Processing Line

Carrot Processing Line Automatic Dumpling Making Machine

Automatic Dumpling Making Machine Cookie Production Line

Cookie Production Line Pasteurized Milk Processing Line

Pasteurized Milk Processing Line Pita Production Line

Pita Production Line