Fully Automatic Commercial Pasta Production Line - Chinese Manufacturer, Factory, Supplier

Introduction

For food factories and large-scale pasta manufacturers, a fully automated commercial pasta production line is an essential investment to boost productivity, ensure consistent quality, and reduce labor costs. This high-performance solution is designed to meet the demanding needs of large-scale production while providing flexibility and precision.

Key Features of the Fully Automatic Pasta Production Line

High Production Capacity

Our fully automated pasta production line is engineered to handle large volumes of pasta production efficiently. With the ability to produce up to 500 kg of pasta per hour, it is ideal for high-output factories and large food production operations. Whether producing spaghetti, macaroni, or specialty pasta, this line meets the high-volume demands of industrial manufacturers.Complete Automation

This system automates every aspect of the pasta production process, from dough preparation, extrusion, and cutting, to drying and packaging. Minimized human intervention results in reduced labor costs and greater production consistency. The automated control system allows operators to monitor and adjust parameters with ease, ensuring smooth operation and reduced downtime.Customizable Production Capabilities

The line offers full customization options to meet specific production needs. With adjustable settings for pasta shape, thickness, and length, this system is adaptable for various types of pasta, including traditional forms like spaghetti and innovative pasta shapes. The customizable molds ensure flexibility in production, making it suitable for manufacturers offering a diverse range of pasta products.Technical Specifications & Energy Efficiency

Built with high-quality stainless steel, this production line is durable, corrosion-resistant, and easy to maintain. It features energy-efficient motors and heating systems, helping to reduce operating costs while maintaining consistent quality. The intuitive control interface ensures ease of use and reduces training time for operators.

Why Choose Our Fully Automatic Pasta Production Line?

Scalability: Easily scalable to meet the growing demands of large food factories.

Reduced Operational Costs: Automation cuts labor and operational costs.

Consistent Quality: High precision machinery ensures uniform pasta quality.

Sustainability: Energy-efficient design supports environmentally conscious production.

Conclusion & Call-to-Action

Upgrade your pasta production capabilities with a fully automated commercial pasta production line designed for high-output, efficiency, and flexibility. Contact us to discuss your specific production needs and request a detailed quote for this advanced solution.

Biscuit Making Machine

Biscuit Making Machine Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Dual-Roll Steamed Bun Machine

Dual-Roll Steamed Bun Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Machine

Pasta Machine Multifunction Pasta Machine

Multifunction Pasta Machine Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler Carrot Processing Line

Carrot Processing Line YL-980 Digital Metal Detector

YL-980 Digital Metal Detector Automatic Sausage Clipper Machine

Automatic Sausage Clipper Machine Meat Bun Machine

Meat Bun Machine Canned Fruit Production Line Equipment

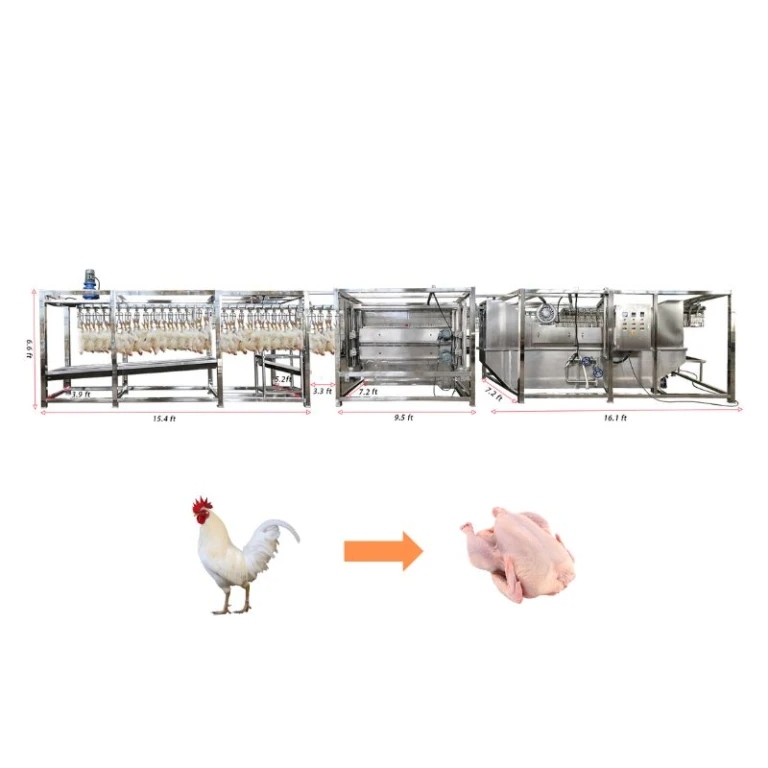

Canned Fruit Production Line Equipment Chicken Production Line

Chicken Production Line Pet Canned Food Production Line

Pet Canned Food Production Line