Pineapple Can Food Production Line - Chinese Manufacturer, Factory, Supplier

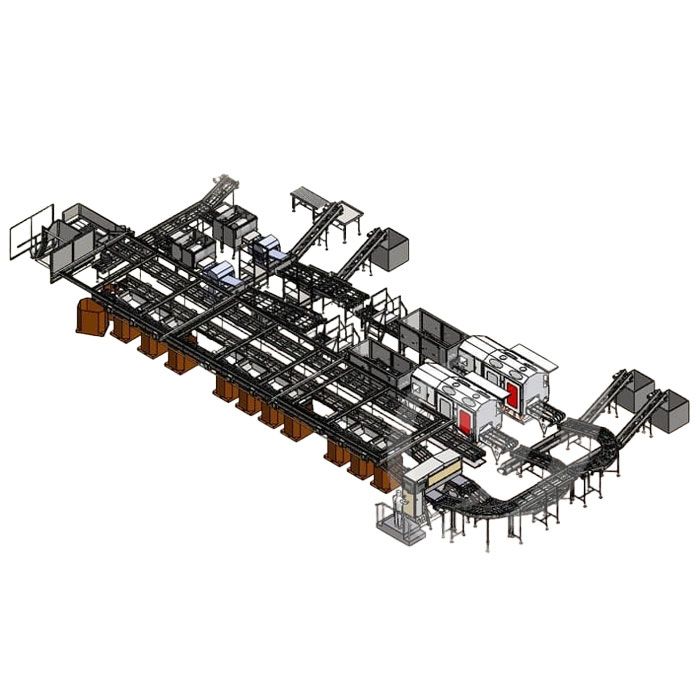

The pineapple can food production line is a fully automated system designed to transform fresh pineapples into safe, high-quality canned products that meet international food industry standards. It combines efficiency, precision, and hygiene, enabling food manufacturers to produce a wide variety of pineapple products while reducing operational costs and labor intensity.

The process begins with raw pineapple reception and careful sorting to ensure only premium fruit enters production. Automated washing systems remove impurities, while peeling and coring machines streamline the preparation process with accuracy and speed. The fruit is then cut into rings, chunks, tidbits, or crushed pineapple, depending on product requirements. Once prepared, the pineapple pieces are blanched to preserve color, texture, and nutrients before filling.

Advanced filling systems place the prepared pineapple into cans or jars, along with syrup, juice, or light brine. Precision control ensures consistent filling levels, reducing waste and guaranteeing product uniformity. Airtight sealing machines follow, preventing contamination and maintaining product freshness. Sterilization, often carried out using retort technology, eliminates harmful microorganisms while safeguarding the fruit’s natural sweetness and aroma. The production line concludes with rapid cooling, labeling, and packaging, preparing the canned pineapples for market distribution.

The pineapple can food production line offers remarkable flexibility. It can handle diverse product formats—such as pineapple rings for desserts, chunks for cooking, or crushed pineapple for beverages and baked goods. Packaging versatility is also a key advantage, supporting tin cans, glass jars, and retort pouches for both domestic sales and international exports.

Hygiene and compliance are at the core of its design. Constructed with stainless steel for easy cleaning and long-term durability, the line aligns with HACCP, ISO22000, and GMP certifications, ensuring every batch meets strict food safety standards. Automated monitoring systems oversee sterilization temperature, filling accuracy, and sealing integrity, providing consistent quality control across production.

As global demand for convenient, tropical fruit products continues to grow, investing in a pineapple can food production line allows manufacturers to expand production capacity, meet consumer expectations, and secure a stronger foothold in competitive markets. By delivering premium canned pineapple with natural taste and extended shelf life, producers can achieve higher returns, build brand reputation, and capture growth opportunities worldwide.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Braised Pork Belly Can Production Line

Braised Pork Belly Can Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Lamian Noodles Processing Production Line

Lamian Noodles Processing Production Line Vacuum Stuffing Machine

Vacuum Stuffing Machine Vacuum Meat Tumbler

Vacuum Meat Tumbler Double-Door Steaming Cabinet with Viewing Window

Double-Door Steaming Cabinet with Viewing Window Meat Shredding Machine

Meat Shredding Machine Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine Frozen Meat Grinder

Frozen Meat Grinder Meat Bun Machine

Meat Bun Machine