How Much Does It Cost to Invest in a Canned Goods Production Line?

In today’s rapidly growing food manufacturing industry, canned food production remains one of the most profitable and stable business investments. With increasing global demand for long-shelf-life food products, investing in a canned goods production line has become an attractive option for manufacturers worldwide. However, one of the most common and essential questions entrepreneurs and investors ask is:

👉 “How much does it cost to start a canned goods production line?”

The answer depends on several factors—such as production capacity, level of automation, type of product, and quality standards. In this comprehensive guide, we’ll break down the cost structure, influencing factors, investment range, ROI expectations, and tips for cost optimization when setting up a canned food production line.

1. Overview: Why Invest in a Canned Goods Production Line?

Before diving into numbers, let’s understand why canned food manufacturing continues to be a lucrative and future-proof investment.

1.1 Market Demand and Growth

The global canned food market is valued at over USD 100 billion, and it continues to expand due to:

Increasing demand for ready-to-eat and long-shelf-life products

Growth in urban populations with busy lifestyles

Rising awareness about food preservation and waste reduction

Expanding export opportunities, especially in Asia, the Middle East, and Africa

1.2 Wide Range of Applications

Canning technology applies to numerous food categories, such as:

Canned fish and seafood (tuna, sardine, mackerel)

Canned fruits and vegetables (tomato paste, pineapple, beans, corn, mushrooms)

Canned meat and poultry (beef, chicken, luncheon meat)

Canned sauces and soups

This versatility allows manufacturers to diversify their product lines and adapt to market trends quickly.

1.3 Long-Term Profitability

While the initial investment is capital-intensive, a properly designed and automated production line can provide:

High production efficiency

Low labor cost

Minimal food waste

Consistent product quality

High export potential

2. Main Cost Components of a Canned Goods Production Line

The total investment cost varies significantly based on capacity, automation level, and product category. However, it can be divided into several main components:

2.1 Equipment Cost

This is the largest portion of your investment, typically accounting for 40–60% of total setup costs.

Key equipment includes:

| Equipment | Function | Estimated Cost Range (USD) |

|---|---|---|

| Raw Material Handling & Washing System | Cleaning fruits, vegetables, or meat before processing | $10,000 – $50,000 |

| Cutting, Blanching & Pre-Cooking Machines | Preparation before filling | $15,000 – $80,000 |

| Filling & Seaming Machines | Filling cans and sealing lids hermetically | $20,000 – $150,000 |

| Sterilization & Retort System | Ensures food safety and shelf stability | $30,000 – $200,000 |

| Cooling & Drying Equipment | Post-sterilization processing | $10,000 – $50,000 |

| Labeling & Packaging Line | For branding and export preparation | $10,000 – $60,000 |

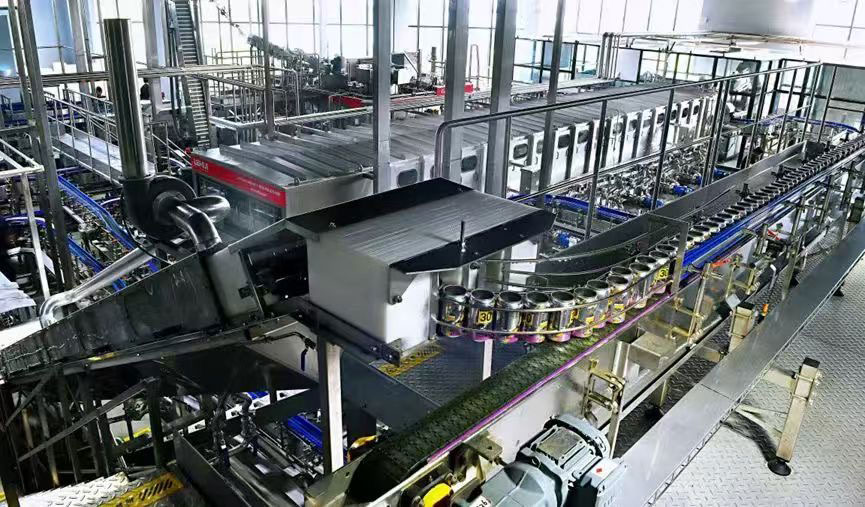

| Conveyor System & Automation Controls | For continuous production flow | $10,000 – $100,000 |

➡️ Total Estimated Equipment Investment:

Small-scale semi-automatic line: $100,000 – $250,000

Medium-scale automated line: $300,000 – $800,000

Large-scale full automation line: $1 million – $3 million+

2.2 Infrastructure and Facility Cost

These include:

Factory building or rental: $50,000 – $500,000 (depending on size and location)

Utilities installation (electricity, water, steam, air): $20,000 – $100,000

Cold storage and warehouse setup: $30,000 – $150,000

Flooring, drainage, and hygiene systems: $10,000 – $80,000

2.3 Labor and Training Cost

Initial staff hiring and training may cost $10,000 – $50,000, depending on the level of automation.

Fully automatic systems may require 5–10 operators per shift

Manual or semi-automatic lines may need 20–40 workers

2.4 Raw Material and Packaging Cost

This will vary based on product type:

Cans and lids: $0.03–$0.08 per unit

Labels and cartons: $0.01–$0.05 per unit

Raw food materials: Depending on seasonal and regional variation

For startups, the initial stock of materials might require $10,000 – $100,000.

2.5 Certification and Licensing Cost

You may need to invest in:

Food safety certification (HACCP, ISO22000): $5,000 – $20,000

Export licenses, customs registration, and inspection: $2,000 – $10,000

Local government permits and testing: $3,000 – $15,000

2.6 Logistics, Marketing, and Contingency Costs

Equipment transport and customs clearance: $10,000 – $50,000

Marketing and branding: $5,000 – $20,000

Spare parts and contingency: 5–10% of total investment

3. Investment Scale Examples

Let’s break down cost scenarios based on business scale:

| Scale | Production Capacity | Automation Level | Total Investment Range |

|---|---|---|---|

| Small-Scale Startup | 1,000–3,000 cans/hour | Semi-automatic | $100,000 – $300,000 |

| Medium Factory | 5,000–10,000 cans/hour | Partially automated | $400,000 – $1,000,000 |

| Large Industrial Plant | 15,000–30,000 cans/hour | Fully automated | $1.5M – $3.5M+ |

4. Factors Influencing the Total Cost

Several variables can change your overall investment amount:

4.1 Product Type

Meat and fish canning lines require sterilization under high pressure, which increases cost.

Vegetable or fruit canning lines are simpler and cheaper to operate.

4.2 Production Capacity

The larger your target output, the higher your initial cost—but also the lower your unit cost per can.

4.3 Level of Automation

Manual line: lower initial investment, but higher labor cost and lower consistency.

Fully automated line: higher cost but much better ROI long-term.

4.4 Material of Equipment

Stainless steel (SUS304/SUS316) is preferred for food hygiene. Higher-grade steel and durable components increase equipment lifespan but add to cost.

4.5 Supplier and Country of Origin

Chinese manufacturers offer competitive prices and strong after-sales support.

European or Japanese brands cost 30–60% more but offer advanced technology.

5. Expected Return on Investment (ROI)

Let’s estimate potential returns for a medium-scale plant:

| Item | Estimate |

|---|---|

| Production | 8,000 cans/hour × 8 hours/day × 25 days/month = 1.6 million cans/month |

| Average Profit per Can | $0.05–$0.15 |

| Monthly Gross Profit | $80,000 – $240,000 |

| Annual Gross Profit | $960,000 – $2.8 million |

| Payback Period | 1.5–3 years |

With proper marketing and export channels, most factories achieve full cost recovery within 24–36 months.

6. How to Reduce Investment and Operating Costs

6.1 Choose Local or Chinese Suppliers

Chinese equipment manufacturers such as JBT, Newcrown, Loyal, and EasyReal offer high-performance machines at 30–50% lower costs than European suppliers.

6.2 Invest in Energy-Efficient Equipment

Modern canning lines use steam recovery systems, automatic temperature control, and smart power management, which can save 15–25% in energy bills.

6.3 Optimize Factory Layout

Efficient layout reduces material movement, lowers labor needs, and minimizes downtime.

6.4 Adopt Automation Gradually

Start with semi-automatic systems and upgrade later as demand increases—this spreads capital expenditure over time.

6.5 Implement Preventive Maintenance

Regular maintenance prevents breakdowns that can lead to costly delays and product losses.

7. Hidden Costs to Consider

Even experienced investors often overlook the following:

Downtime and calibration costs during setup

Employee training and certification

Testing and pilot runs before full-scale production

Product R&D and formulation costs

Software and control system updates

These can add 5–10% to your total project cost.

8. How to Choose the Right Equipment Manufacturer

When selecting your canning line supplier, consider the following checklist:

| Criteria | Why It Matters |

|---|---|

| Experience | Established manufacturers understand complex food safety standards |

| Customization Capability | Each product (fish, meat, tomato) requires tailored processes |

| After-Sales Support | Local technicians and spare parts availability reduce downtime |

| Global Export Certifications | CE, ISO, SGS certifications ensure international compliance |

| References and Case Studies | Proven success with previous projects builds confidence |

9. Step-by-Step Process to Set Up a Canning Production Line

Market Feasibility Study – Analyze target markets and competition.

Product Design & Recipe Development – Determine can size, ingredients, and formulation.

Equipment Selection – Choose capacity and automation level based on your forecast.

Factory Design & Layout Planning – Optimize workflow for hygiene and efficiency.

Installation & Commissioning – Calibrate machines and run test batches.

Staff Training & Certification – Ensure operators meet food safety standards.

Marketing & Distribution Setup – Build your brand, logistics, and partnerships.

10. Case Example: Medium-Scale Fish Canning Factory

A seafood company in Southeast Asia invested $750,000 in a semi-automated sardine canning line with:

2 retort sterilizers

1 automatic seamer

1 filling machine

1 labeling & packing line

Results after 18 months:

Monthly output: 1.2 million cans

Net profit margin: 15%

ROI achieved in less than 2 years

Top 10 Commercial Canned Food Production Line Equipment Manufacturers In China

11. Future Trends in Canned Food Manufacturing

11.1 Smart Automation & IoT Monitoring

Advanced systems use IoT sensors to monitor temperature, pressure, and productivity in real time.

11.2 Sustainable Packaging

Eco-friendly cans and reduced waste packaging are becoming industry standards.

11.3 AI-Driven Quality Control

Artificial intelligence now helps detect can defects, ensuring 100% quality consistency.

11.4 Integrated Turnkey Solutions

Turnkey plants—from raw material processing to final packaging—are now more cost-efficient and faster to deploy.

12. Conclusion

The cost to invest in a canned goods production line typically ranges from $100,000 to over $3 million, depending on capacity, automation, and quality requirements. While the investment may seem high, the long-term returns, market demand, and export potential make it one of the most profitable ventures in the food manufacturing sector.

By carefully planning your budget, selecting a reliable manufacturer, and focusing on automation and energy efficiency, you can build a modern, competitive, and profitable canned food factory that delivers consistent quality and strong ROI for years to come.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?