Tomato Canning Production Line - Chinese Manufacturer, Factory, Supplier

The Tomato Canning Production Line is a fully automated industrial solution designed for high-efficiency processing of fresh tomatoes into canned products such as tomato paste, sauce, peeled tomatoes, and diced tomatoes. It integrates modern food engineering technology with advanced automation to deliver consistent quality, high yield, and compliance with international food safety standards.

The production process begins with tomato reception and sorting, where fresh tomatoes are screened for ripeness and quality. Next, the tomatoes are thoroughly washed and blanched, which removes impurities, softens the skin, and inactivates enzymes to maintain natural color and taste.

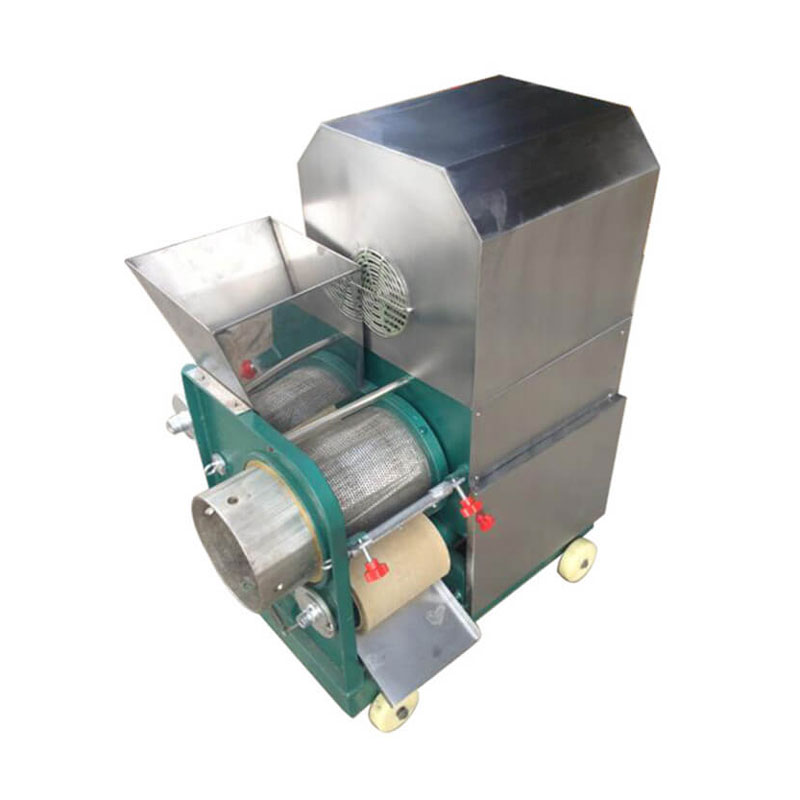

After cleaning, the tomatoes are crushed and pulped, separating seeds and skin from the pulp. The resulting tomato mass can then be concentrated to the desired consistency using vacuum evaporators or forced circulation concentrators, suitable for both sauce and paste production. Precise concentration ensures stable Brix levels while preserving nutrients and flavor.

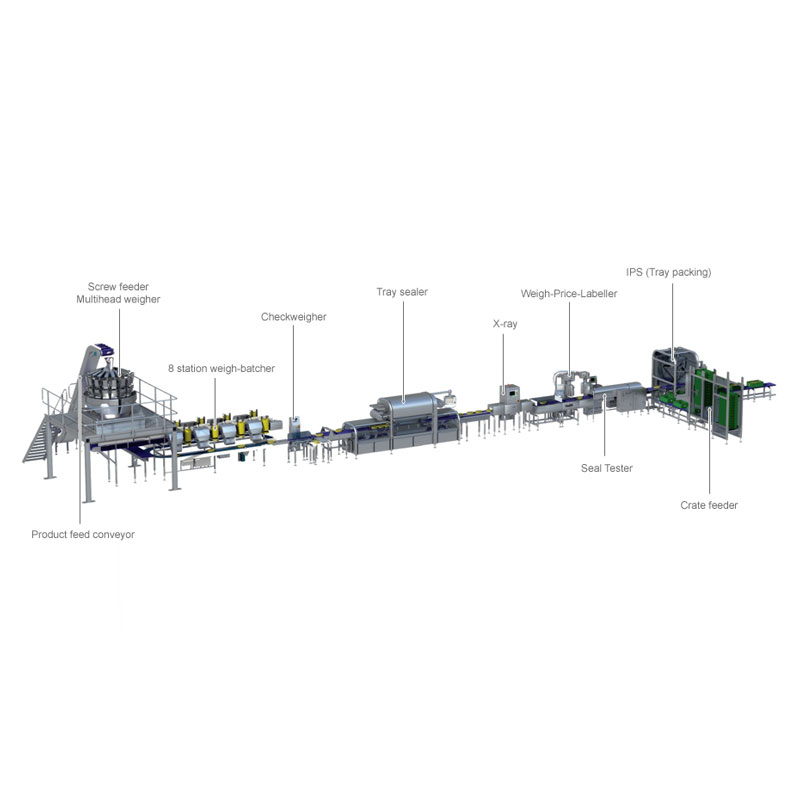

The line includes automatic filling and sealing machines, which accurately dose tomato paste or pieces into sterilized cans, jars, or pouches. The filled containers are then processed in retort sterilization systems, extending shelf life and ensuring food safety without compromising texture or taste. After sterilization, the products are cooled and sent to labeling and packaging units for final dispatch.

Constructed with high-grade stainless steel (SUS304/316), the equipment is resistant to corrosion, easy to clean, and meets HACCP, ISO22000, and CE standards. The entire line is controlled by PLC systems, providing real-time monitoring, fault detection, and production data tracking. This automation reduces labor costs, improves operational efficiency, and ensures uniform product quality across all batches.

The Tomato Canning Production Line can be customized according to capacity and product specifications, supporting small, medium, and large-scale factories. Optional modules include CIP cleaning systems, automatic can depalletizers, and auxiliary blending or mixing tanks for special formulations.

With extensive international experience, Qingdao Hongshengyuanlin Co., Ltd. delivers turnkey solutions including factory design, equipment supply, installation, commissioning, and operator training. Our systems have been successfully deployed in Asia, Africa, the Middle East, and South America, helping clients optimize production, increase efficiency, and maintain high standards of food safety.

Choosing our Tomato Canning Production Line ensures reliable performance, energy efficiency, and scalable production, making it an ideal solution for modern tomato processing enterprises.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Vacuum Meat Tumbler

Vacuum Meat Tumbler Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Poultry Line

Poultry Line Lamian Noodles Processing Production Line

Lamian Noodles Processing Production Line Automatic Fresh Meat Dicing Machine

Automatic Fresh Meat Dicing Machine Jam Canned Production Line

Jam Canned Production Line Fish Deboner Machine

Fish Deboner Machine Tofu Production Line

Tofu Production Line