Automatic Food Processing Line - Chinese Manufacturer, Factory, Supplier

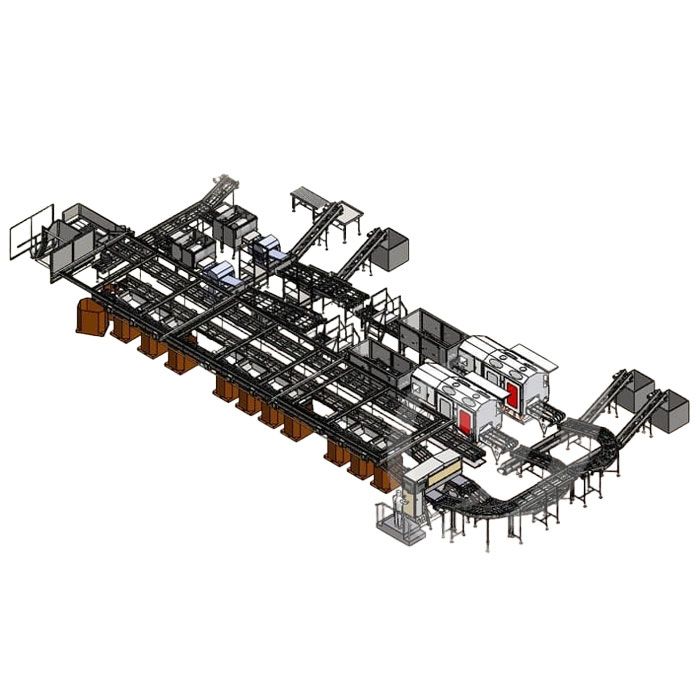

In today’s fast-evolving food manufacturing landscape, businesses must prioritize efficiency, consistency, food safety, and scalability to stay competitive. Our Automatic Food Processing Line is a state-of-the-art, end-to-end automation solution engineered specifically for B2B clients — including food processing plants, central kitchens, ready-to-eat meal producers, catering chains, co-manufacturers (OEM/ODM), and large-scale food distributors.

This fully automated food production system integrates advanced technologies to streamline every stage of food processing — from raw material handling to final packaging — ensuring maximum throughput, minimal labor costs, and full compliance with global food safety standards.

🔧 What Is an Automatic Food Processing Line?

An Automatic Food Processing Line is a modular, intelligent production system that automates the entire food manufacturing workflow. By combining PLC control systems, HMI interfaces, industrial robotics, AI-powered vision inspection, IoT connectivity, and data analytics, this line enables 24/7 continuous operation with minimal human intervention.

Designed for high-volume production, it supports a wide range of food types, including:

Ready-to-eat meals (RTE)

Pre-cut fruits & vegetables

Cooked meats and poultry

Seafood processing

Sauces, dressings, and condiments

Frozen and chilled convenience foods

🏭 Key Modules of the Automated Food Production Line

1. Automated Raw Material Handling & Conveying

Vacuum or belt-fed systems for bulk ingredients

Smart weighing and dosing units ensure precise input

Seamless integration with warehouse logistics (ERP/WMS)

2. Automatic Washing & Sorting System

Multi-stage cleaning: bubble wash, spray rinse, drum scrubbing

Integrated AI vision sorting removes foreign objects (stones, plastics) and defective items

Water recycling and filtration reduce consumption by up to 60%

3. Precision Cutting & Forming Equipment

High-speed slicers, dicers, shredders, mincers, and formers

Adjustable blade configurations for customized shapes and sizes

Suitable for meat, vegetables, cheese, and more

4. Automated Cooking & Thermal Processing

Steam cooking, frying, baking, sous-vide, and sterilization (UHT, retort)

Real-time temperature, time, and humidity control

Energy-efficient design with heat recovery systems

5. Intelligent Seasoning & Mixing System

Automated dosing of liquid and powder seasonings

Recipe management software allows quick changeover between flavor profiles

Ideal for regional or customized product lines

6. High-Speed Packaging Line

Options: vacuum sealing, MAP (Modified Atmosphere Packaging), flow wrapping, tray sealing

Compatible with pouches, cups, trays, and cans

Output: up to 120 packs per minute, depending on configuration

7. In-Line Quality Inspection & Traceability

Metal detectors, X-ray inspection, checkweighers, and camera-based defect detection

Full batch traceability via QR codes or RFID tags

Compliant with HACCP, ISO 22000, FDA FSMA, and EU food safety regulations

8. CIP/SIP Cleaning & Sanitization System

Fully automated Clean-in-Place (CIP) and Sterilize-in-Place (SIP) functions

Reduces downtime and ensures hygienic processing

Meets GMP and 3A sanitary standards

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Jam Making Equipment

Jam Making Equipment Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment Fish Slicer Machine

Fish Slicer Machine Pizza Cone Equipment

Pizza Cone Equipment Braised Pork Belly Can Production Line

Braised Pork Belly Can Production Line Beverage Production Line

Beverage Production Line Meat Grinding Machine

Meat Grinding Machine