Commercial Potato Chips Making Machine - Chinese Manufacturer, Factory, Supplier

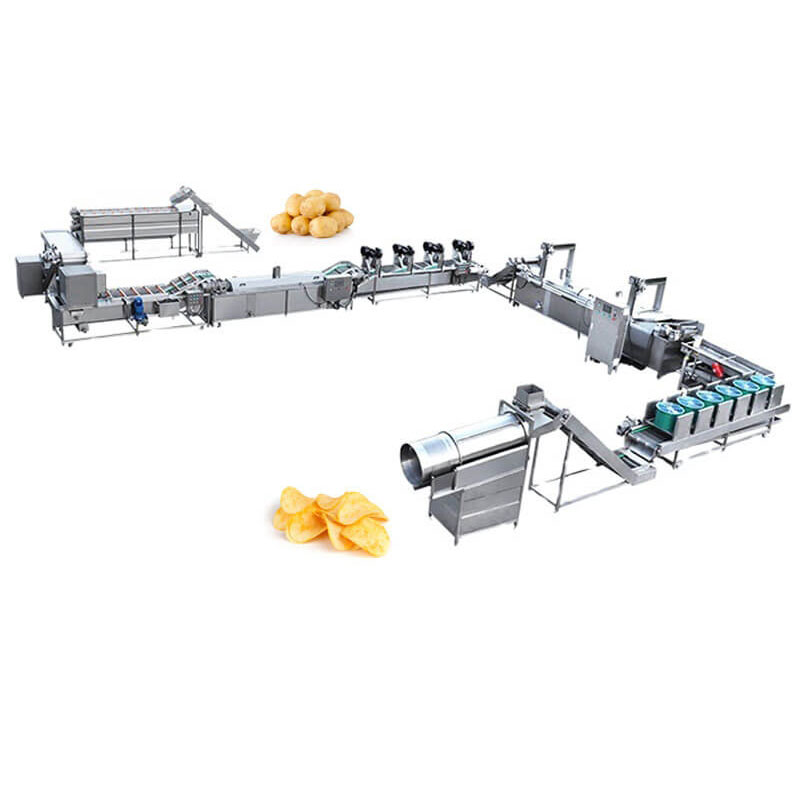

The commercial potato chips making machine is a high-efficiency solution designed for large-scale snack food production. It enables manufacturers to produce uniform, crispy, and high-quality potato chips with consistent taste and appearance. From slicing and washing to frying, seasoning, and packaging, this equipment streamlines the entire production process, reducing labor and ensuring hygiene.

Modern machines are constructed from high-grade stainless steel, ensuring durability, corrosion resistance, and easy cleaning. High-speed slicing blades produce even potato slices, while automated frying systems control oil temperature and cooking time precisely to achieve perfect crispness. Integrated seasoning units allow for consistent flavor coating, enhancing product quality and consumer appeal.

The machine is highly versatile and can be adapted for different types of potato chips, including thin, thick, wavy, or kettle-style chips. Optional features such as continuous frying, automatic oil filtration, and real-time monitoring improve production efficiency, reduce operational costs, and maintain food safety standards.

Applications of commercial potato chips making machines include snack factories, food processing plants, and ready-to-eat meal producers. They are suitable for producing large batches for retail, wholesale, or private-label brands, meeting high-demand market requirements with consistent quality and output.

Qingdao Hongshengyuanlin Co., Ltd. provides not only standalone potato chips machines but also complete turnkey snack production lines. With extensive experience in designing, integrating, and exporting automated food processing systems globally, the company delivers tailored solutions that optimize productivity, ensure hygiene compliance, and minimize production costs. Our services include factory layout planning, installation supervision, operator training, and long-term maintenance, helping clients achieve maximum efficiency and competitive advantage.

Potato Processing Line

Potato Processing Line Potato Chip Line

Potato Chip Line Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Twist Potato Machine

Twist Potato Machine Potato Washing&Peeling Machine

Potato Washing&Peeling Machine Potato Chips Instant Freezer

Potato Chips Instant Freezer Rotary Drum Potato Chips Seasoning Machine

Rotary Drum Potato Chips Seasoning Machine Brush Potato Washing Peeling Machine

Brush Potato Washing Peeling Machine Screw Potato Peeling Washing Machine

Screw Potato Peeling Washing Machine 250kg/Hr Compound Potato Chips Frying Plant

250kg/Hr Compound Potato Chips Frying Plant Compound Potato Chips Baking Line

Compound Potato Chips Baking Line Semi-automatic Potato Crisps Production Line

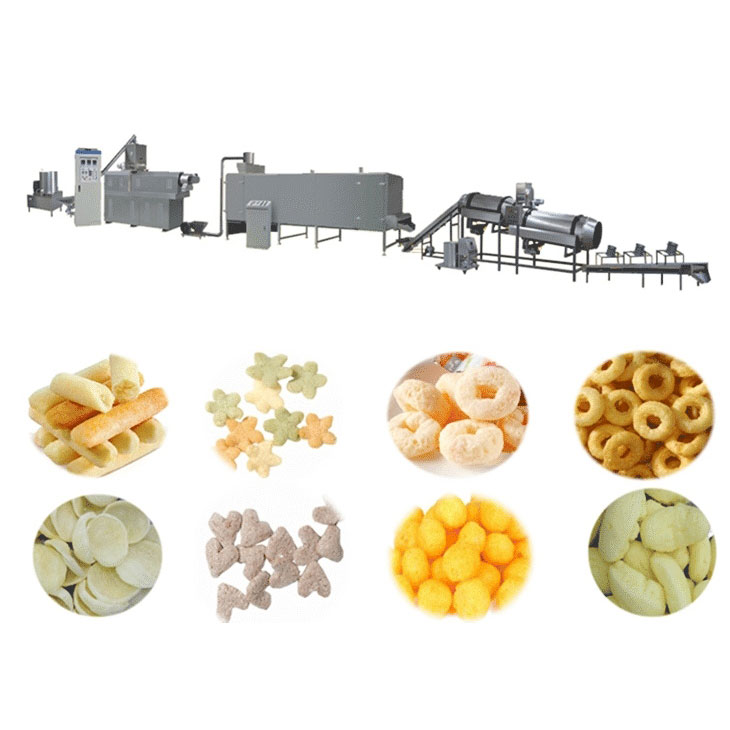

Semi-automatic Potato Crisps Production Line Snack Production Line

Snack Production Line Pet Canned Food Production Line

Pet Canned Food Production Line AM Series Crescent Ice Maker

AM Series Crescent Ice Maker Automatic Sausage Clipper Machine

Automatic Sausage Clipper Machine Multifunctional Noodle Making Machine

Multifunctional Noodle Making Machine Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Standard Integrated Weighing and Packaging Machine

Standard Integrated Weighing and Packaging Machine Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder