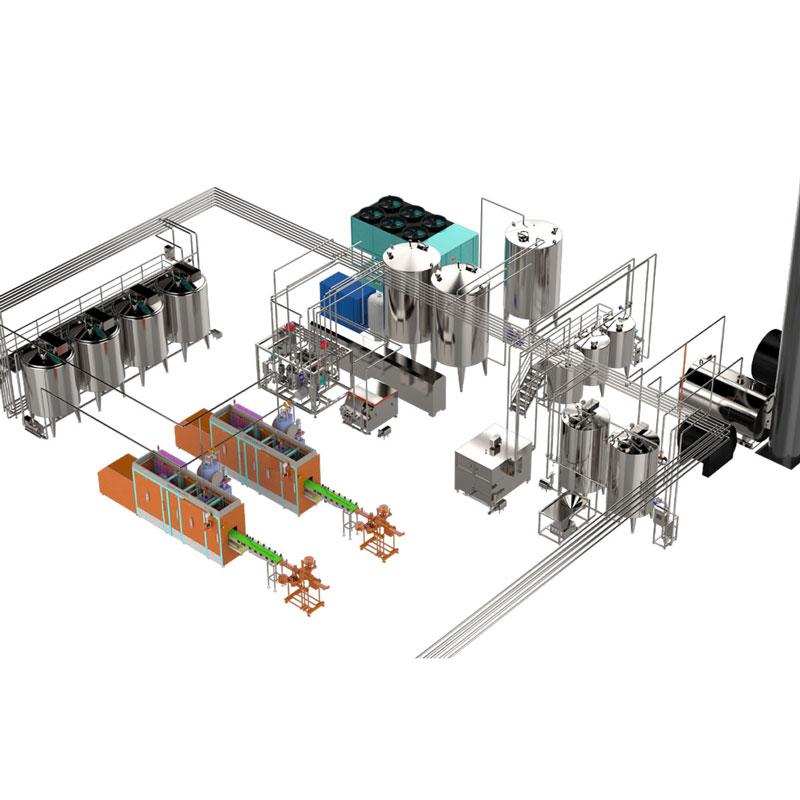

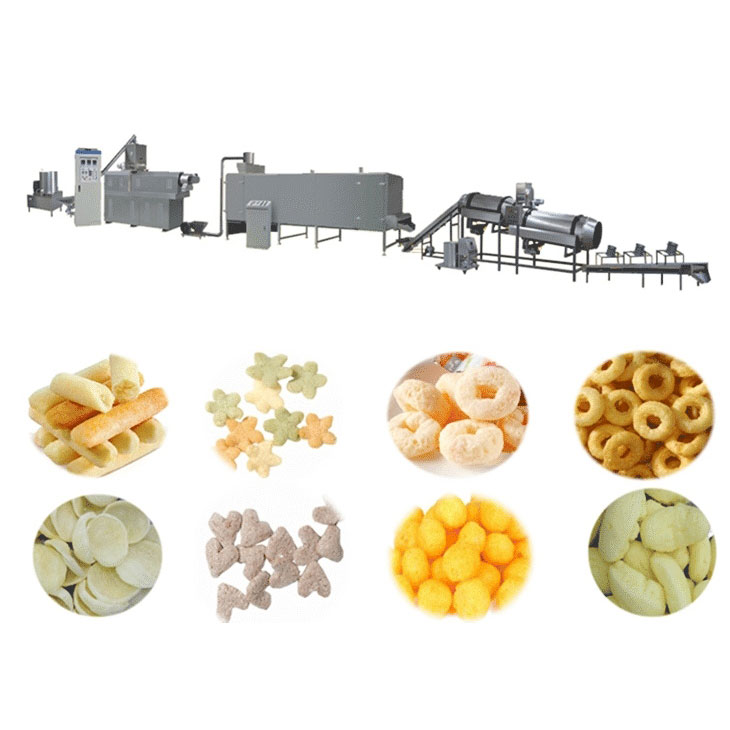

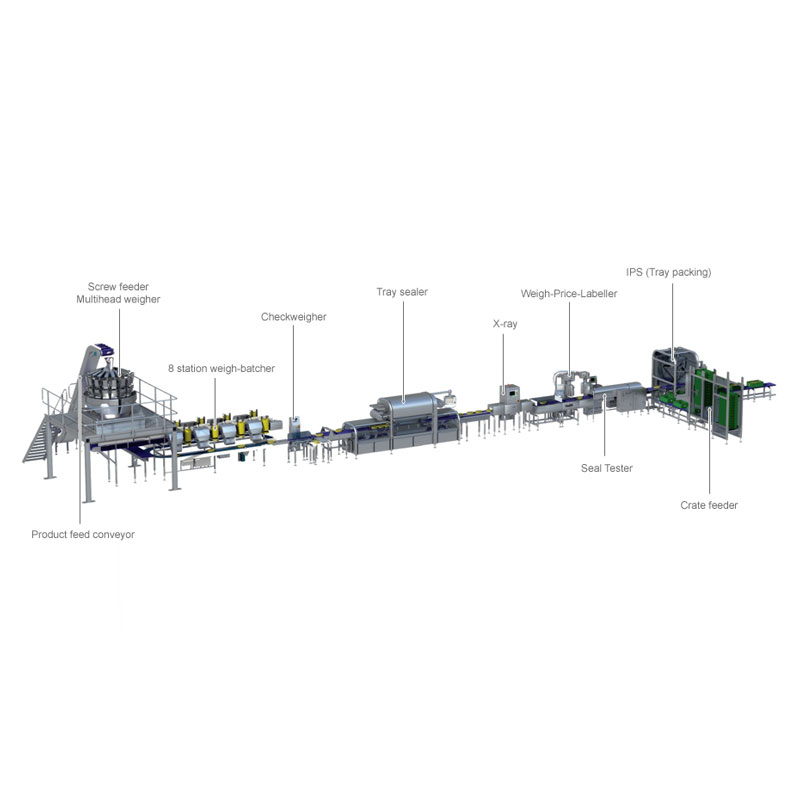

Our food production lines are meticulously designed with your specific industry needs in mind. Whether you are in the meat, dairy, bakery, snack, or beverage production sectors, we offer state-of-the-art, fully automated, high-efficiency production lines that not only streamline your operations but also significantly reduce labor costs and enhance overall throughput. Our solutions are crafted to ensure maximum productivity while maintaining superior product quality.

In the highly competitive food production industry, time is money, and efficiency is key. Our automated production lines are designed to minimize human error, optimize processing speed, and deliver consistent results, all while maintaining the highest standards of hygiene and safety. Whether you’re looking to produce large volumes of meat, dairy, bakery items, or snack foods, our solutions are tailored to suit your unique production requirements, ensuring that your operations run smoothly, even at peak demand.

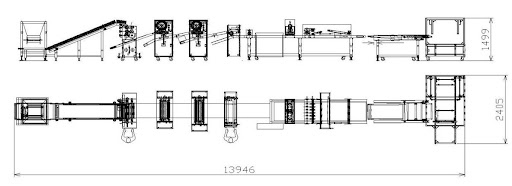

Each system is customizable to meet your specific needs, whether you require more flexibility in production, varying product specifications, or enhanced automation levels. We offer scalable solutions that grow with your business, allowing you to start with a system that fits your current capacity and expand as your business evolves. Our production lines integrate cutting-edge technologies that not only increase production efficiency but also help to reduce waste, lower operational costs, and minimize energy consumption.

By choosing our food production lines, you can be assured of top-notch performance, from the initial setup to ongoing operations. Our comprehensive solutions guarantee consistent product quality, reduce downtime, and help you maintain a competitive edge in an ever-evolving market. With our focus on quality, consistency, and scalability, we empower your business to achieve long-term growth while delivering outstanding results across all stages of production.

Key Features of Our Food Production Line Solutions

- Full Automation: Reduce manual labor and improve efficiency.

- Custom Design: Tailored solutions to meet your specific production needs.

- High-Performance Machinery: Stable, durable, and energy-saving.

- Food-Grade Materials: Hygienic and compliant with CE, FDA, HACCP standards.

- Flexible Layouts: Modular systems for future expansion or upgrades.

- Global Service Network: Installation, training, technical support worldwide.

Industries We Serve

Maintenance and Repair Tips for Food Production Line

A customized Food Production Line is designed to meet specific production needs, often making it more complex than standard equipment. Proper maintenance and repair are essential to ensure the Food Production Line operates efficiently and maintains stable performance. Below are some important maintenance and repair recommendations:

1. Regular Cleaning

-

Clean all parts of the Food Production Line regularly to prevent the buildup of food residues. This is crucial for maintaining hygienic conditions and preventing corrosion or damage to parts.

-

Use food-grade cleaning agents and avoid chemicals that may harm the equipment’s surface.

2. Routine Inspection of Key Components

-

Inspect critical components of the Food Production Line on a regular basis, including motors, blades, and transmission devices, to ensure they remain in good working condition.

-

Check for signs of wear, looseness, or damage and replace problematic parts promptly to avoid unexpected failures.

3. Lubrication

-

Lubricate mechanical components of the Food Production Line on time to reduce friction, minimize wear, and extend service life.

-

Select appropriate lubricants that comply with food production safety standards to avoid contamination.

4. Professional Maintenance

-

Arrange for regular comprehensive inspections and maintenance services conducted by professional technicians.

-

For complex or highly specialized custom components within the Food Production Line, it is advisable to consult the original equipment manufacturer for maintenance and repair services.

5. Operator Training

-

Provide professional training for operators on the proper usage and maintenance procedures of the Food Production Line to ensure they understand correct operation methods and essential maintenance steps.

-

Effective training extends the lifespan of the equipment and minimizes damage caused by human error.

6. Record Keeping and Documentation

-

Maintain detailed records of all maintenance and repair activities for the Food Production Line. These records help monitor the equipment’s history, assess current condition, and predict when parts may need replacement or when major overhauls are required.