Beef Canned Food Production Line - Chinese Manufacturer, Factory, Supplier

The beef Canned Food Production Line is a state-of-the-art system engineered to handle every stage of beef canning with efficiency, precision, and strict adherence to global food safety regulations. It covers an integrated process flow that begins with raw meat cutting, trimming, and weighing, followed by cooking, seasoning, and sauce preparation. Advanced filling equipment then ensures accurate dosing of beef chunks, gravy, or broth into cans or jars, after which sealing, sterilization, and rapid cooling guarantee a long shelf life without compromising flavor or nutritional value.

Designed for industrial-scale operations, the production line reduces dependency on manual labor while delivering consistent product quality. Automated sterilization systems, such as retort or autoclave technology, effectively eliminate harmful microorganisms, ensuring the safety of every batch. Precise temperature and pressure control protect the natural tenderness of beef and preserve its original taste, making the final product highly appealing to end consumers.

Flexibility is a hallmark of this production line. It can accommodate various product formats, including plain beef, beef with vegetables, or spiced beef stews, as well as diverse packaging types such as tin cans, glass jars, and retort pouches. The modular design allows manufacturers to expand or adapt their production capacity in response to changing market demand, whether for small-batch specialty foods or high-volume commercial output.

With the global demand for protein-rich, ready-to-eat meals on the rise, the beef canned food production line provides food manufacturers with a competitive edge. It ensures reliable production performance, cost efficiency through reduced waste, and compliance with HACCP, ISO, and GMP standards. By integrating cutting-edge automation, processors can improve throughput, optimize resource utilization, and achieve long-term operational sustainability.

For enterprises aiming to strengthen their position in both domestic and international markets, investing in a modern beef canned food production line is not just a technical upgrade but a strategic move toward brand credibility, product diversification, and global market expansion.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Bowl Cutter

Bowl Cutter Full-View Electric Oven

Full-View Electric Oven Remove The Machine

Remove The Machine Pelmeni Making Machine

Pelmeni Making Machine Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Industrial Microwave Drying Machine

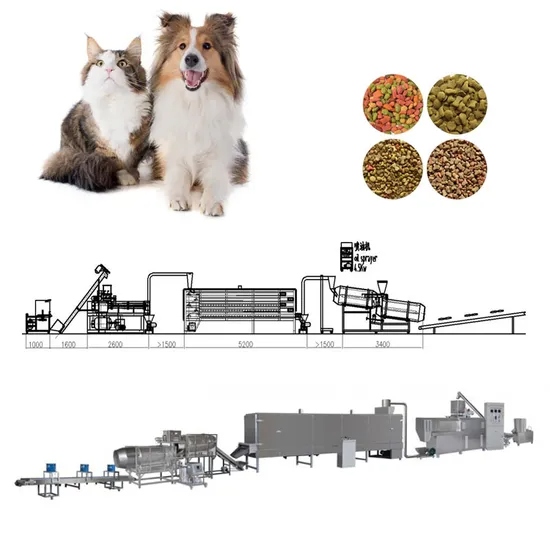

Industrial Microwave Drying Machine Dry Pet Food Production Line

Dry Pet Food Production Line YL-W-04 Commercial Water Purification Equipment

YL-W-04 Commercial Water Purification Equipment