Dairy Processing Equipment Manufacturers - Chinese Manufacturer, Factory, Supplier

Dairy processing equipment manufacturers provide essential machinery for transforming raw milk into high-quality, safe, and market-ready dairy products such as pasteurized milk, yogurt, cheese, butter, cream, and flavored milk. These manufacturers offer solutions that combine automation, hygiene, and precision control to meet the growing global demand for safe and nutritious dairy products.

A modern dairy processing line typically includes the following key modules:

Milk Receiving and Chilling Units: Quickly cool raw milk to 4°C to preserve freshness and inhibit bacterial growth.

Pasteurization Systems: Plate or tubular pasteurizers heat milk to 72–75°C for 15–20 seconds, effectively eliminating pathogens while preserving nutritional value.

Homogenizers and Separators: Ensure uniform fat distribution and efficient separation of cream from milk.

Storage and Aging Tanks: Food-grade stainless steel tanks with CIP (Clean-in-Place) systems maintain hygiene and product quality.

Filling and Packaging Units: Automated fillers and packers for bottles, cartons, or pouches ensure hygienic and efficient packaging.

Leading dairy processing equipment manufacturers provide fully customizable solutions suitable for small, medium, and large-scale operations. Equipment can be manual, semi-automatic, or fully automated, with PLC-controlled systems enabling real-time monitoring of temperature, flow, and pressure. Capacities typically range from 500 liters/day for small farms to 10,000+ liters/day for industrial plants, allowing scalability as production demand grows.

Manufacturers also prioritize compliance with international food safety and quality standards such as HACCP, ISO22000, GMP, and CE certification, ensuring that the entire process—from raw milk intake to final packaging—meets stringent hygiene and quality requirements.

Qingdao Hongshengyuanlin Co., Ltd. is recognized as a reliable dairy processing equipment manufacturer in China, delivering turnkey dairy solutions worldwide. The company offers engineering design, equipment customization, factory layout planning, installation, and operator training. With successful projects across Asia, Africa, and the Middle East, Hongshengyuanlin integrates automation, robust construction, and professional after-sales service, helping clients achieve high efficiency, consistent quality, and cost-effective production.

Partnering with an experienced dairy processing equipment manufacturer ensures faster project implementation, reduced labor costs, and superior product consistency, providing a competitive advantage in the global dairy industry.

Types of Dairy Processing Equipment & Applications

| Category | Main Equipment | Core Function | Typical Applications |

|---|---|---|---|

| Milk Receiving & Storage | Milk tanks, chilling tanks, milk silos | Preserve raw milk freshness and prevent bacterial growth | Raw milk storage for farms, cooperatives, and factories |

| Pasteurization Systems | Plate pasteurizers, tubular pasteurizers | Kill harmful microorganisms while maintaining nutrients | Pasteurized milk, flavored milk, cream |

| Homogenization & Separation | Homogenizers, centrifugal separators | Ensure uniform fat distribution and cream separation | Milk, cream, yogurt production |

| Mixing & Blending | Ribbon mixers, paddle mixers, vacuum mixers | Combine ingredients consistently | Flavored milk, yogurt, milkshakes |

| Fermentation & Aging Tanks | Yogurt fermenters, cheese vats, aging tanks | Controlled fermentation and maturation | Yogurt, cheese, cultured dairy products |

| Filling & Packaging | Aseptic fillers, bottle fillers, pouch fillers, carton packers | Package products hygienically and efficiently | Milk, yogurt, cream, flavored beverages |

| Cooling & Freezing | Blast chillers, spiral freezers | Rapidly cool or freeze dairy products to extend shelf life | Ice cream, frozen yogurt, cheese |

| Cleaning & Sanitation | CIP systems, sterilizers, cleaning tanks | Maintain hygiene and prevent contamination | All dairy processing stages |

| Automation & Control Systems | PLC panels, SCADA systems, sensors | Centralized monitoring, process control, and optimization | Fully automated dairy production lines |

| Quality Control & Inspection | Metal detectors, flow meters, temperature sensors | Ensure safety, uniformity, and compliance | Milk, cheese, yogurt, butter, ice cream |

Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Carrot Processing Line

Carrot Processing Line Dairy Lines

Dairy Lines Potato Processing Line

Potato Processing Line Vegetable Processing Line

Vegetable Processing Line Fish Processing Line

Fish Processing Line Honey Processing Equipment

Honey Processing Equipment Fish Food Processing Line

Fish Food Processing Line IQF Processing Line

IQF Processing Line Lamian Noodles Processing Production Line

Lamian Noodles Processing Production Line Milk Production Line

Milk Production Line Hydraulic Sausage Filling Machine

Hydraulic Sausage Filling Machine Chop Meat Machine

Chop Meat Machine Fish Slicer Machine

Fish Slicer Machine AM Series Crescent Ice Maker

AM Series Crescent Ice Maker Apple Canning Production Line

Apple Canning Production Line Fully Automatic Potato Chips Line

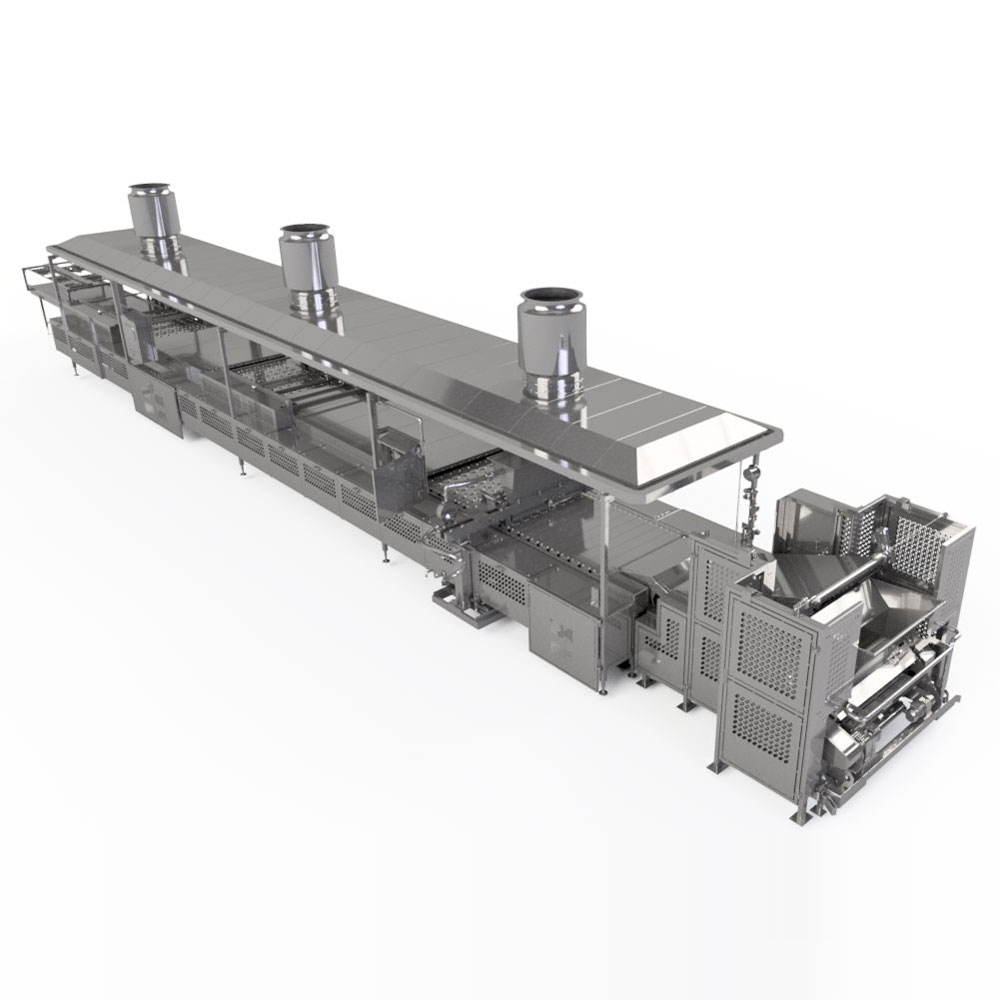

Fully Automatic Potato Chips Line Pancake Production Line

Pancake Production Line