Salmon Canned Production Line - Chinese Manufacturer, Factory, Supplier

The Salmon Canned Production Line combines advanced engineering with stringent food safety protocols to create a seamless and reliable production solution for the seafood industry. Built for continuous operation, it transforms raw salmon into ready-to-ship canned products with minimal manual handling and maximum efficiency.

The process initiates with automated unloading systems that accommodate whole fish or pre-cut fillets. High-capacity washing tunnels ensure contaminants are removed before processing. Specialized thawing units, where required, maintain optimal moisture levels, preserving the delicate structure of the salmon. Mechanical trimming and deboning modules then prepare uniform cuts, improving yield and reducing waste.

Central to the Salmon Canned Production Line is its synchronized filling and can-loading system, capable of managing solid pieces, flakes, or minced formulations. Each portion is precisely weighed and placed in pre-sterilized cans before liquid mediums—ranging from light brine to rich sauces—are dispensed. Advanced seaming technology guarantees airtight closures that withstand subsequent sterilization.

Post-sealing, the line employs retort processing chambers that deliver exact heat penetration for reliable sterilization while maintaining the product’s natural color and omega-rich composition. Automated cooling, labeling, and case-packing systems finalize the process, preparing the product for global distribution.

Equipped with inline monitoring, data recording, and traceability systems, the Salmon Canned Production Line ensures compliance with HACCP, FDA, and EU food safety standards. Its modular design supports scalability, allowing facilities to expand capacity or integrate new technologies as market demands evolve.

With its combination of efficiency, product integrity, and compliance, the Salmon Canned Production Line enables seafood manufacturers to achieve consistent production output while delivering premium-quality canned salmon that satisfies consumers worldwide.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Automatic Sausage Linking Machine

Automatic Sausage Linking Machine Dough Roller Machine

Dough Roller Machine Flour Mixing Machine

Flour Mixing Machine Bowl Cutter

Bowl Cutter YL-W-03 Commercial Water Purification Equipment

YL-W-03 Commercial Water Purification Equipment Meat Pie Maker Machine

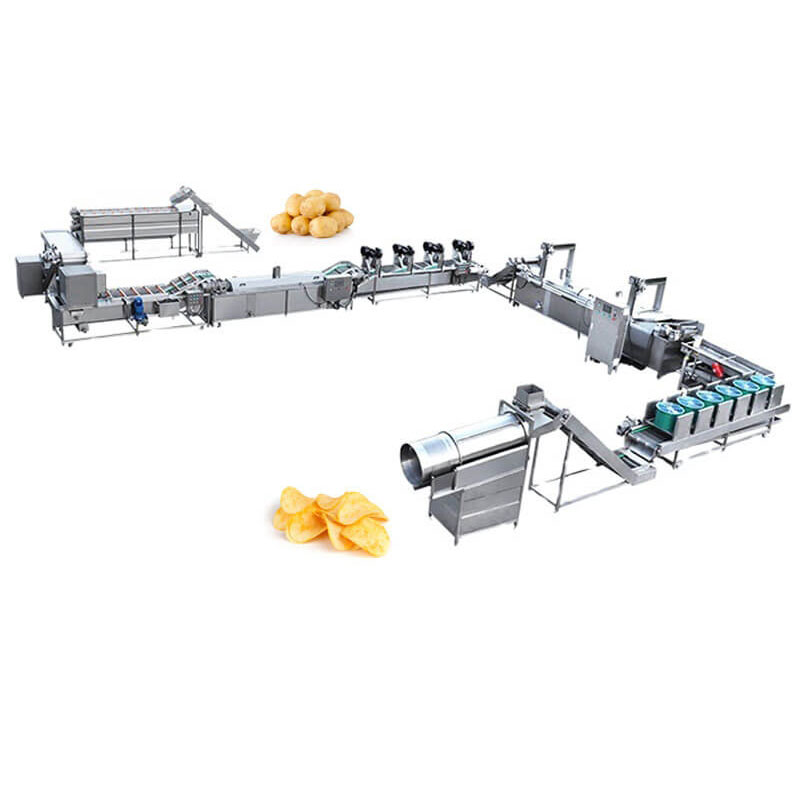

Meat Pie Maker Machine Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Chicken Plucker Machine

Chicken Plucker Machine