Fresh Meat Canned Food Production Line - Chinese Manufacturer, Factory, Supplier

The Fresh Meat Canned Food Production Line is a high-efficiency, fully automated system designed to process various types of fresh meat — including beef, pork, chicken, duck, and lamb — into ready-to-eat canned products. It integrates the entire workflow from raw meat handling to sterilized and packaged goods, ensuring consistent quality, long shelf life, and full compliance with international food safety standards such as HACCP, ISO22000, and FDA. This production line is ideal for meat processing plants, food factories, and B2B manufacturers looking to achieve high productivity and hygiene control.

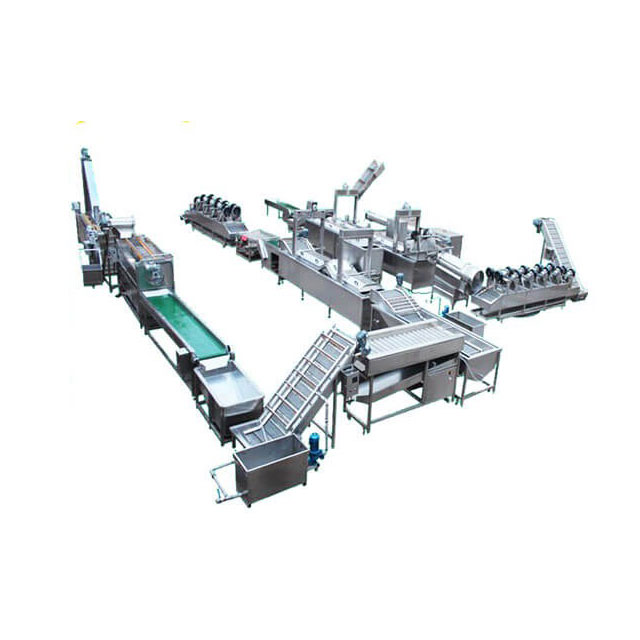

A complete fresh meat canning production line typically includes the following major stages: meat receiving and inspection, trimming and cutting, pre-cooking or blanching, automatic weighing and filling, broth or sauce dosing, vacuum sealing, sterilization, cooling, labeling, and final packaging. All equipment components are made from food-grade stainless steel (SUS304/316) to ensure corrosion resistance, durability, and easy cleaning — essential for maintaining sanitary conditions in meat processing facilities.

The line incorporates PLC-controlled automation systems that provide precise temperature and pressure regulation during sterilization, real-time data monitoring, and automatic fault detection. These features greatly reduce manual errors, enhance production stability, and improve product traceability. Retort sterilizers are used to eliminate microorganisms while retaining the natural texture, flavor, and nutritional value of the meat.

Customization is one of the key advantages of this production line. It can be tailored for different can sizes, meat types, and product formulations (such as in oil, gravy, or brine), as well as for packaging materials including tin cans, aluminum cans, or retort pouches. Optional modules like vacuum filling, automatic sauce dosing, and CIP (Clean-In-Place) systems can be integrated to further increase automation and sanitation efficiency.

For B2B buyers and meat processors, investing in a Fresh Meat Canned Food Production Line offers multiple benefits — including labor cost reduction, increased productivity, stable product quality, and faster market response. It enables food manufacturers to meet global demand for safe, shelf-stable, and convenient canned meat products while maintaining competitive production costs and environmental sustainability.

In summary, the Fresh Meat Canned Food Production Line is a modern, hygienic, and scalable solution that helps meat processors transform raw meat into premium canned products efficiently. Combining automation, flexibility, and food safety, this production line supports long-term business growth and international market expansion.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Frozen French Fries Production Line

Frozen French Fries Production Line Blast Freezer

Blast Freezer Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Cookie Production Line

Cookie Production Line Automatic Meat Mixer Machine

Automatic Meat Mixer Machine Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine YL-W-05 Commercial Water Purification Equipment

YL-W-05 Commercial Water Purification Equipment Gummy Candy Production Line

Gummy Candy Production Line